Maximum availability through precise condition monitoring

In many companies, machine monitoring is not yet based on facts, but rather on empirical values – an approach that is becoming increasingly unreliable as tasks become more complex and staff shortages increase. At the same time, smooth, safe, and cost-efficient operation must be ensured, even in economically challenging times. This makes it all the more important to keep track of the condition of the machines at all times. This is exactly where the new i-STEP Operator comes in: an innovative tool that enables plant managers to monitor machines based on facts and helps them to make their daily work more efficient and forward-looking.

It's that easy

Registration & Self-Service

Registration is very simple: IFE customers can register on the i-STEP Operator Portal using their email address and VAT number. After verification with the IFE customer database, they will receive a confirmation email with their login details within a few working days.

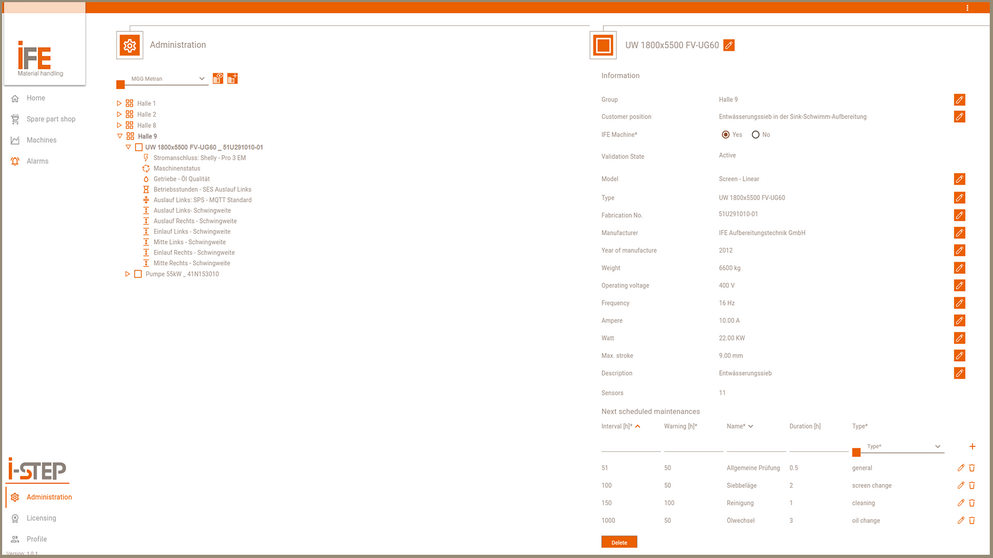

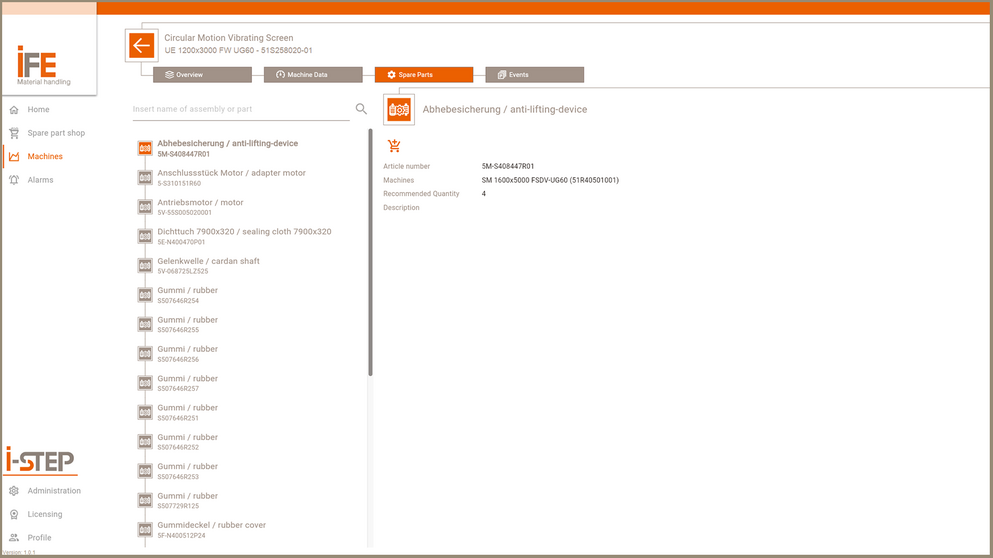

After logging in for the first time, you can register your own IFE machine using the serial number. Here, too, a comparison with the IFE customer database is carried out to ensure data security. Sensors can also be easily created by the user.

The customer can now invite additional employees to the profile and assign roles with different rights. As a “manager,” you have full access, can invite additional users, and create machines and sensors. As an “administrator” within the organization, you have access to the data and dashboards. IFE is happy to provide the necessary support during the setup phase so that you can quickly and fully utilize all the benefits.

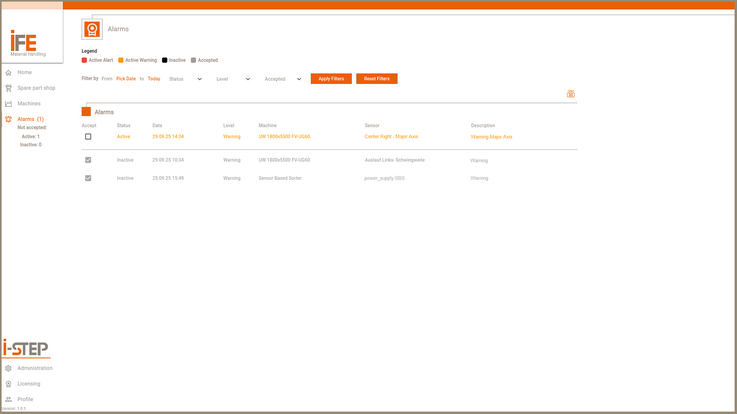

Dashboard & Alarms

Everything at a glance

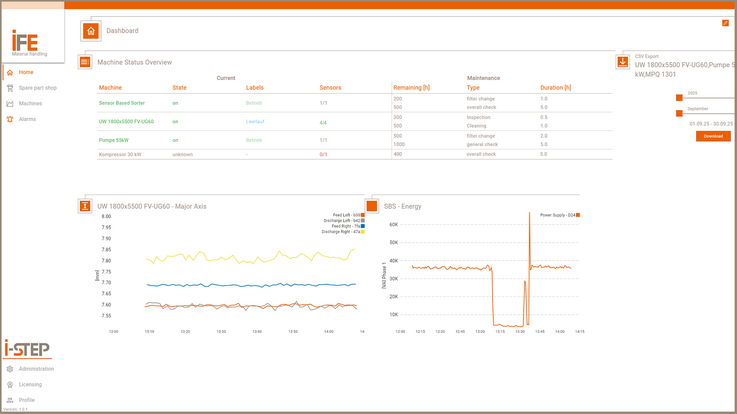

The i-STEP Operator can be customized to suit your needs in many areas. For example, the dashboard can be designed as desired – similar to the home screen of a smartphone. Like “widgets” on a smartphone, diagrams, analyses, and various elements can be placed and resized in the i-STEP Operator using drag & drop. This allows you to see the most important information about your machine park at a glance.

Alarms and notifications can also be customized. It is also possible to receive them via email so that no messages are missed.

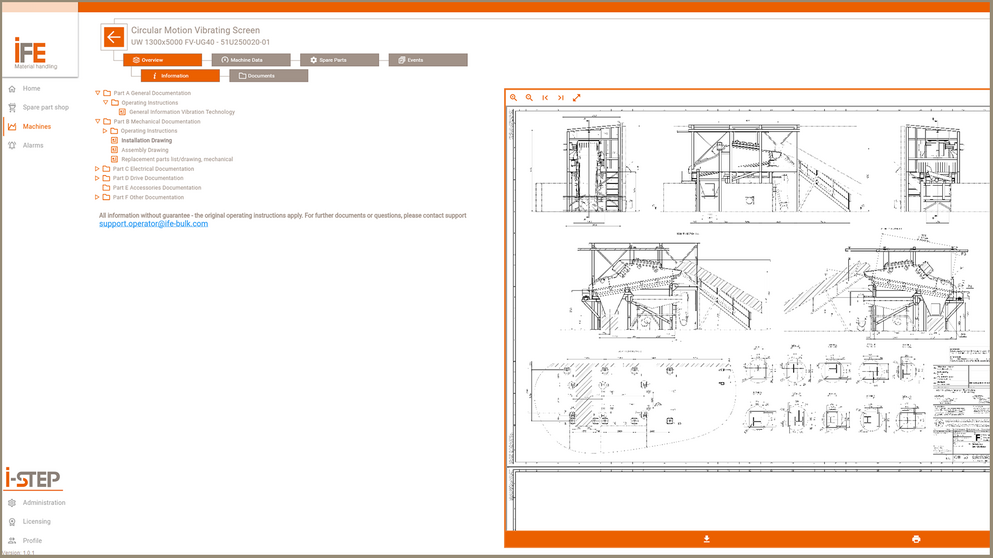

The timeline provides a compact overview of historical events and completed tasks, as well as a preview of upcoming maintenance, cleaning tasks, and much more. If a sensor reports a limit violation, this is also visible in the timeline. In addition to the standard entries that are automatically created when the IFE machine is registered, users can create their own maintenance entries, record events (e.g., unscheduled maintenance), and enter intervals for their own tasks (e.g., cleaning the screen linings every 100 hours). Notifications, e.g. for upcoming tasks, can also be created individually by the user. Entries can also be recorded or deleted retroactively in the timeline. The timeline and individual entries can be printed as an overview, with detailed information, or individually.

Always informed: the i-STEP Wiki

The i-STEP Wiki helps users find specific functions, better understand IFE's digital services, and stay informed about the latest developments. It contains quick guides, tutorials, screenshots, and news about i-STEP Operator. Like the platform itself, the Wiki is available in German and English.

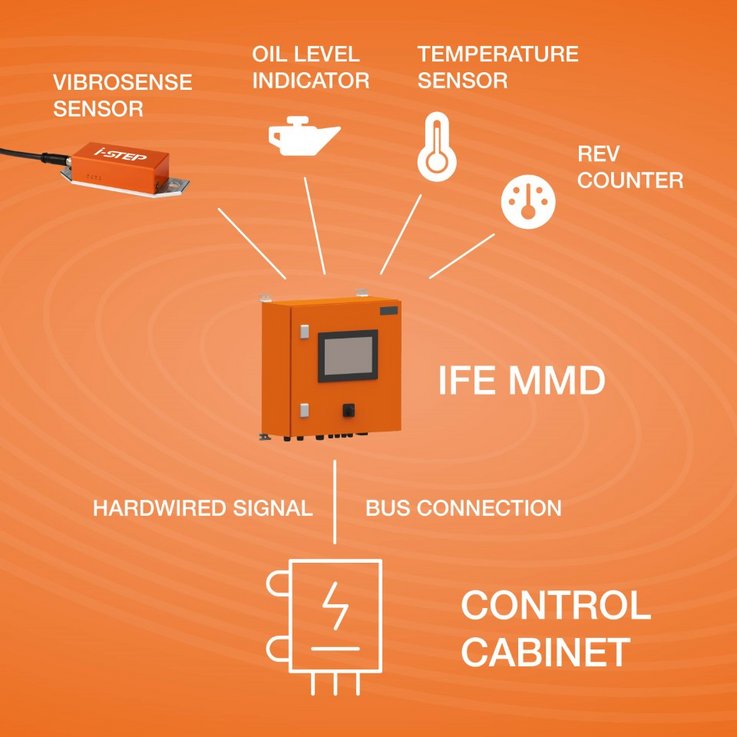

On-site machine monitoring

The IFE Machine Monitoring Device integrates sensor data directly into your control system and enables predefined actions – from warning alerts to automatic shutdown. Depending on your needs, a complete control cabinet can be supplied, or the system with PLC can be installed directly into your existing setup.

And what happens next?

Starting in October 2025, i-STEP Operator will be available to all IFE machine operators. With the “Light” package, they will have free access to the portal, where they will be able to create machines and access related documents with limited functionality. Additional packages, including customized solutions, can be requested from your IFE contact at any time and offer further integration options for sensors, (third-party) machines, and an extended range of functions.

An i-STEP base station is now available as a test kit for interested parties. This includes four Vibrosense sensors, which are installed and configured in your own company together with an IFE employee. The stand-alone solution allows you to test the full version of the i-STEP Operator for an agreed trial period and see the benefits for yourself.

“With the i-STEP Operator, which was developed as a further refinement of i-STEP Workbench, we are delighted to now be taking the next step and providing our customers with a sophisticated tool that makes their day-to-day work noticeably easier, digitizes existing machines, and creates real added value,” summarizes Reinhard Hochstrasser, who is responsible for this product line in the after-sales department at IFE.

Anyone who is now curious can contact their IFE representative directly for further information and to request a personal demo.