THE DIGITAL SOLUTION FOR THE PERMANENT MONITORING OF YOUR MATERIAL HANDLING PROCESSES

In many companies, machine monitoring is not yet based on facts, but rather on empirical values – an approach that is becoming increasingly unreliable as tasks become more complex and staff shortages increase. At the same time, smooth, safe, and cost-efficient operation must be ensured, even in economically challenging times.

This makes it all the more important to keep track of the condition of the machines at all times. This is exactly where the new i-STEP Operator comes in: an innovative tool that enables plant managers to monitor machines based on facts and helps them to make their daily work more efficient and forward-looking.

Sensors

for permanent condition monitoring

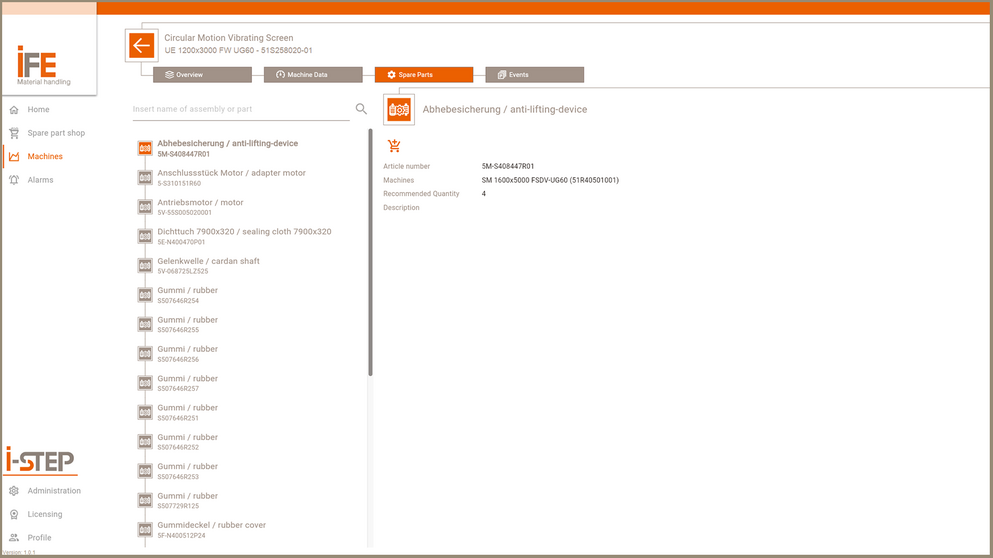

Thanks to various sensors, numerous factors can be monitored for reliable machine operation. Third-party sensors and machines can also be added to the Operator.

Packages

Feature / Function | Light | Basic | Business | Enterprise |

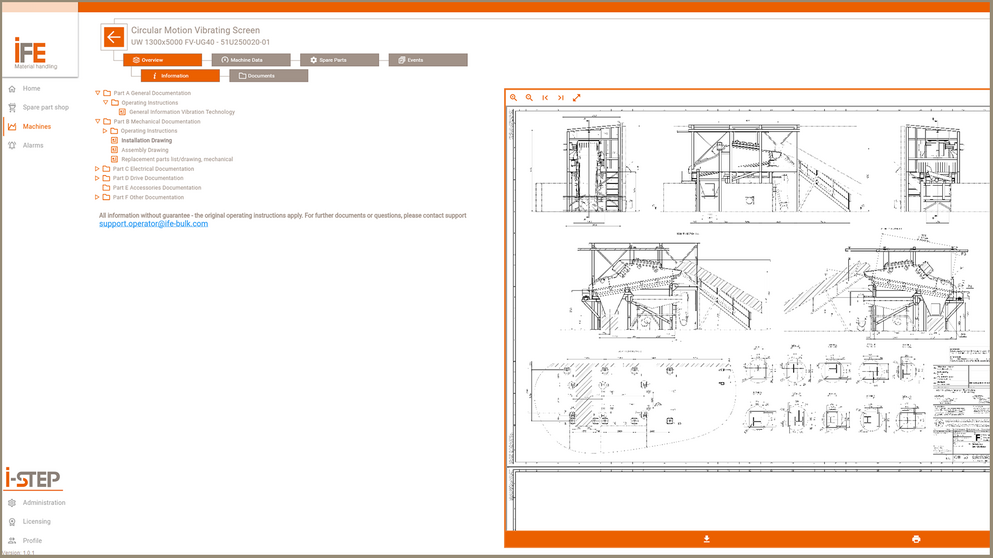

| Basic Functions (Operating instructions, spare parts, IFE document management) | ✓ | ✓ | ✓ | ✓ |

| Online Data Transmission (Transfer and Display of Sensor Data) | x | ✓ | ✓ | ✓ |

| Machine Log (Maintenance, General Events) | x | ✓ | ✓ | ✓ |

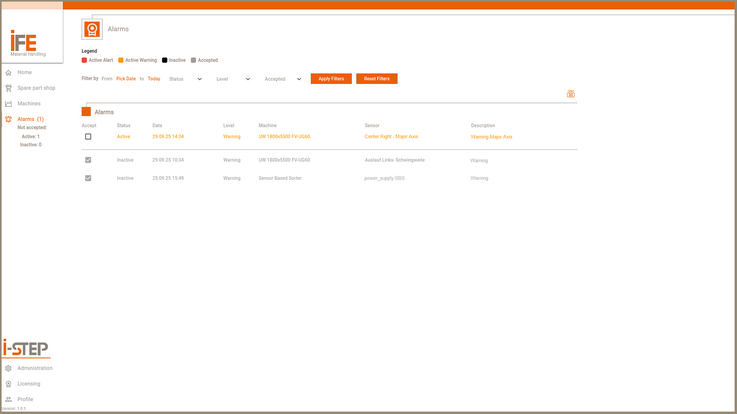

| Alarms (Configurable Thresholds) | x | ✓ | ✓ | ✓ |

| Standard PDF Reporting (Alarms and Events) | x | ✓ | ✓ | ✓ |

| Dynamic Maintenance Planning (Based on Operating Hours) | x | x | ✓ | ✓ |

| Advanced Reporting (BETA) | x | x | ✓ | ✓ |

| Integration of Third-Party Sensors1 | x | x | ✓ | ✓ |

| Custom Developments for Enterprise2 | x | x | x | ✓ |

| Number of Sensors (per Machine) | x | 4+2 | 10+3 | 15+4 |

| Price per Month | free of charge | 290 € | 490 € | 890 € |

| Price per Year | free of charge | 3.306 € (-5%) | 5.586 € (-5%) | 10.146 € (-5%) |

1 Third-party sensors = Sensors not supplied by IFE. Possible IFE sensors include vibration (SES), oil quality and temperature, air pressure, and electrical power.

2 Billed according to actual effort

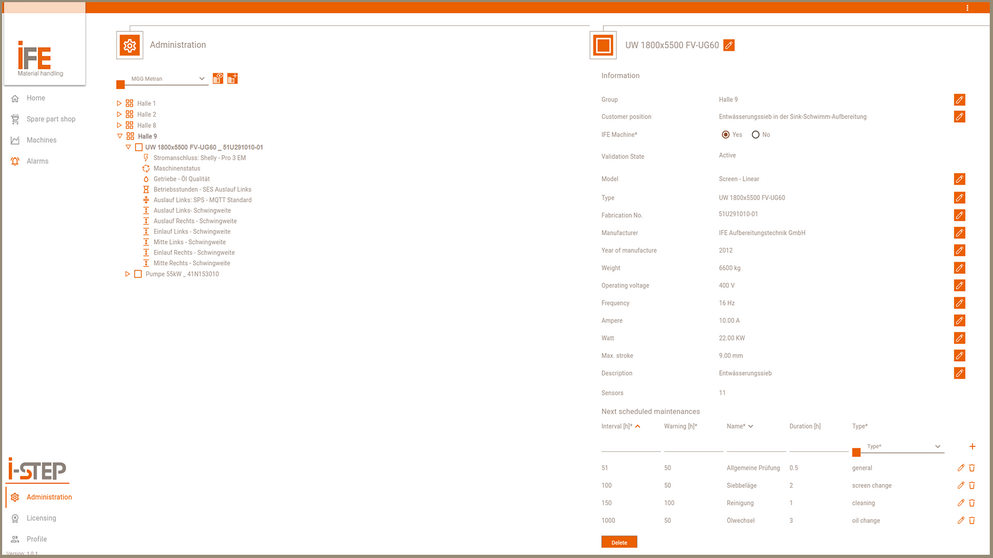

Adding machines and sensors

After logging in for the first time, you can register your own IFE machine using the serial number and machine type. Both details can be found on the nameplate.

Here, too, a comparison with the IFE customer database is carried out to ensure data security.

Sensors can be easily added by the user.

Users & roles

Users can now invite other employees to join the profile and assign roles with different rights.

- Manager

Full access, can invite other users, create machines and sensors - Worker

Has access to the data and dashboards and can also manage alarms and maintenance as well as log events.

IFE is happy to provide the necessary support during the setup phase so that you can quickly and fully utilize all the benefits.

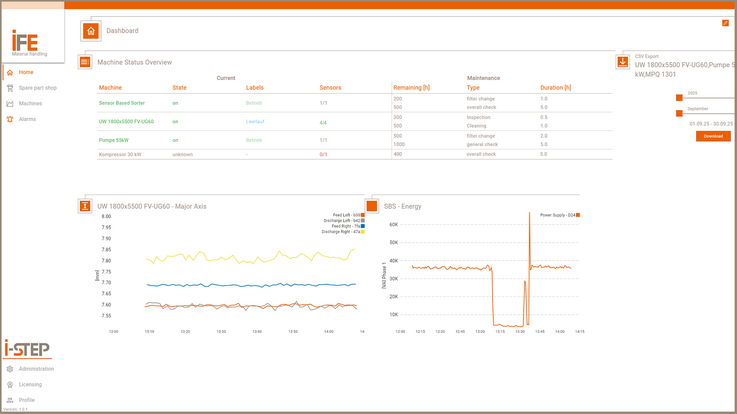

The dashboard can be customized – similar to the home screen of a smartphone. Status indicators, charts, analyses, and other elements can be arranged and resized in the i-STEP Operator using drag & drop. This way, the most important information about your machine park is available at a glance.

The timeline provides a compact overview of historical events and completed tasks, as well as a preview of upcoming maintenance, cleaning tasks, and much more. If a sensor reports a limit violation, this is also visible in the timeline. In addition to the standard entries that are automatically created when the IFE machine is registered, users can create their own maintenance entries, record events (e.g., unscheduled maintenance), and enter intervals for their own tasks (e.g., cleaning the screen linings every 100 hours). Notifications, e.g. for upcoming tasks, can also be created individually by the user. Entries can also be recorded or deleted retroactively in the timeline. The timeline and individual entries can be printed as an overview, with detailed information, or individually.

Base station

The i-STEP base station is a test kit containing four Vibrosense sensors, which are installed and configured at your premises by an IFE employee. This stand-alone solution allows you to test the full version of i-STEP Operator for an agreed trial period and see the benefits for yourself.