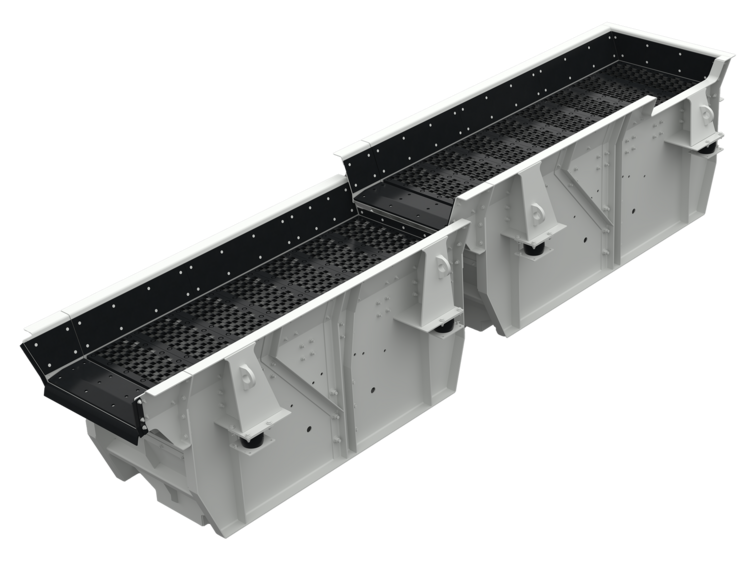

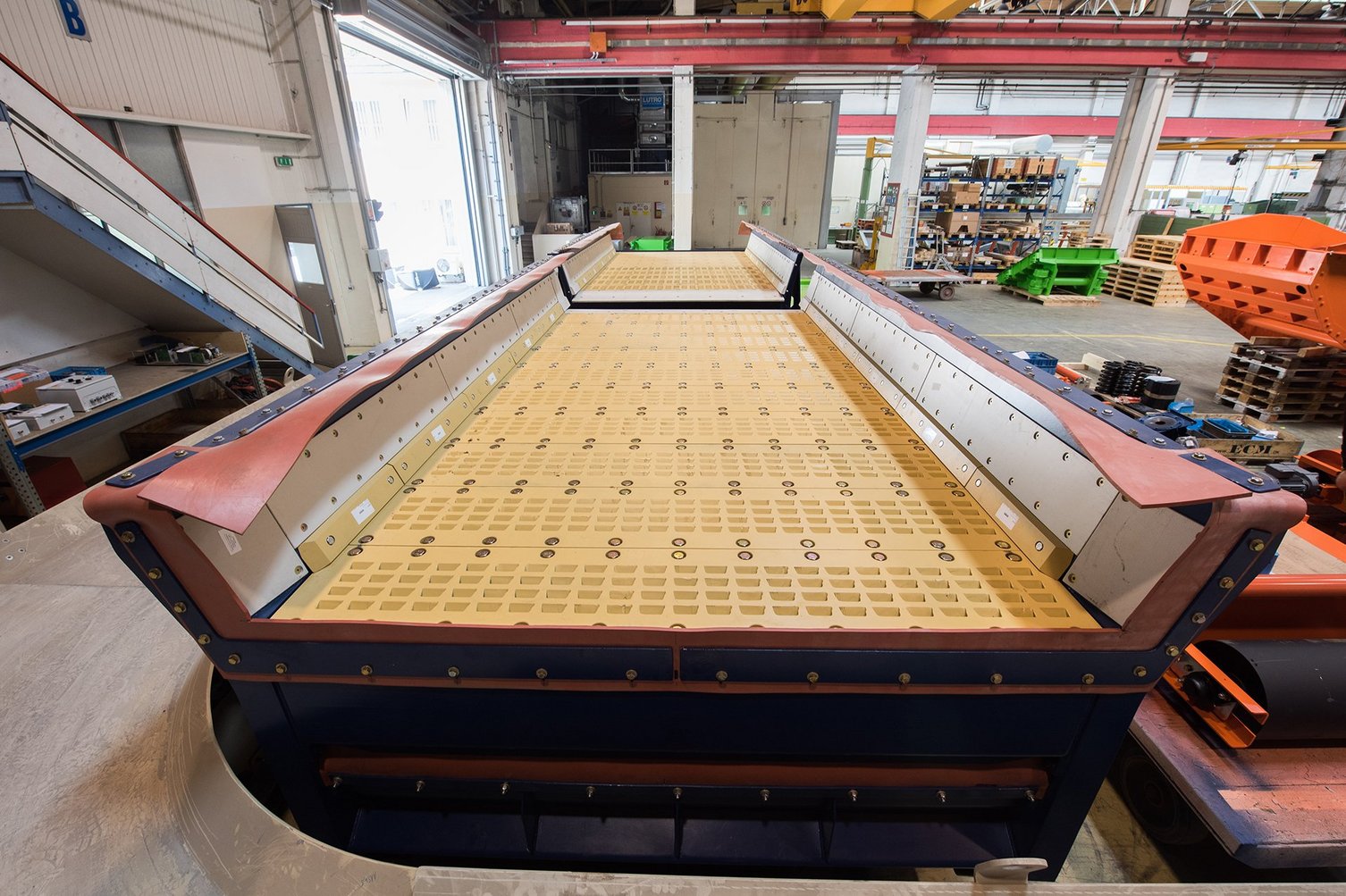

The sand lumps are effectively crushed and fall through the grate openings onto a lower sand conveyor section and are fed into the sand regeneration system as loose sand or crushed lumps. The casting is conveyed by the conveyor movement from the channel and transferred to the subsequent process steps “casting cooling and reading section.” The drive concept with an unbalanced cell and electronic control allows the oscillation angle of the machine to be varied. This allows the separation and conveying behavior to be adapted to different castings.

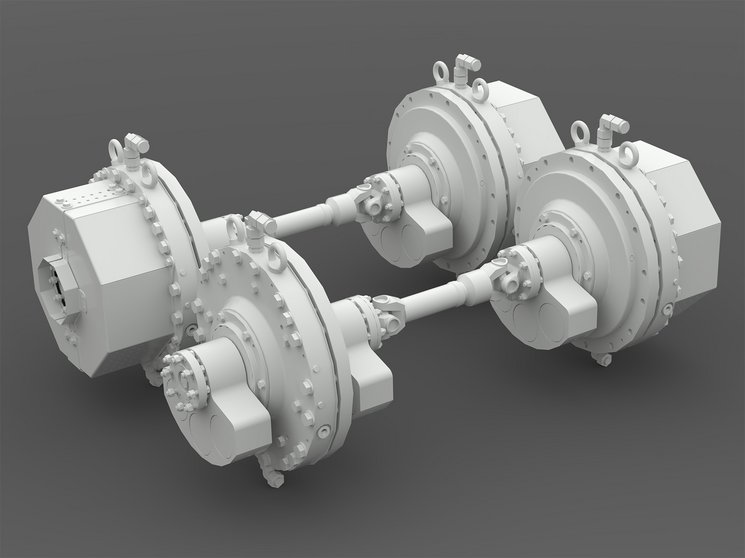

Unbalanced Cells are compact, maintenance-friendly vibratory drives with low noise emission. They consist of highperformance spherical roller bearings, eccentric weights and a cardan shaft connection between two unbalanced cells. The oil bath lubrication ensures a long service life. The working torque can be adjusted using additional weights. Simple replacement of the individual unbalanced cells enables easy maintenance even in very harsh and dusty environments.