At the end of 2023, another IFE AEROSELECTOR was successfully put into operation in the middle of the Bavarian region Oberland. The system with IFE VARIOMAT and magnetic separation was installed at the composting plant in Warngau at the company VIVO Kommunalunternehmen für Abfall-Vermeidung. Since then, the processes on site have been optimized and promising results have been achieved.

Before the introduction of the AEROSELECTOR, VIVO used a mobile solution consisting of a star screen and wind sifter for compost processing, but this did not produce the desired results. The lack of FE separation and stone trap meant that unwanted contaminants ended up in the end product.

In addition, despite repeated screening, there was still a considerable amount of compost in the screen residues. The company was therefore looking for a new solution.

The VIVO team seized the opportunity to tour the AEROSELECTOR facilities at AKG Agrar Kompost GmbH and Brantner Österreich GmbH. Furthermore, material tests conducted at Seiringer Umweltservice GmbH yielded convincing results.

- Specifically, the system impressed with its efficient fraction separation. All relevant fractions (films, FE, stones, compost, structural material) were processed in a single pass. The high purity of the respective material groups was also highly satisfactory.

- Due to a closed rotting system, the input material of VIVO has a high moisture level. With the IFE VARIOMAT, this sticky, moist compost could also be obtained in large quantities.

- Another important argument was the streamlined workflow: Thanks to the generous volume of the hopper, a wheel loader driver can devote himself to other tasks while the machine works efficiently.

- Ultimately, the mechanical engineering itself was also convincing: The AEROSELECTOR meets the highest industrial standards and is characterized by its high-quality workmanship.

The AEROSELECTOR comes to Warngau

After the order was placed at the end of April 2023, the installation took place at the end of November 2023 and commissioning in December. Despite wintry conditions at times, both went smoothly and the system was able to go into operation before Christmas. Experience the construction up close in the time-lapse video!

The hopper feeder has a volume of 25 m³ - enough for the wheel loader driver to devote himself to other tasks while the raw compost is being processed. A magnetic belt roller is integrated at the end of the first conveyor belt. The FE parts are already separated there.

Adjustments were made to accommodate the spatial conditions: The second ascending conveyor belt was installed at a steeper angle and fitted with cleats to enable the material to be conveyed effectively even at this greater incline. Care was taken to ensure that large, round, heavy parts could still run back over the belt and be separated between the two conveyor belts.

The VARIOMAT with its resonance system and flexible screen surfaces ensures that the material is loosened up. The fine compost can be screened here with virtually no blockages.

At the heart of the system - the AEROSELECTOR - the material is first accelerated on a conveyor belt. The transfer area between the acceleration belt and conveyor belt acts additionally as an effective stone trap. The air blown in causes the films to lift off and leads them to the extraction system. The remaining material lands on another conveyor belt. In the subsequent star screen, valuable structural material is recovered and only a small amount of screen residue remains.

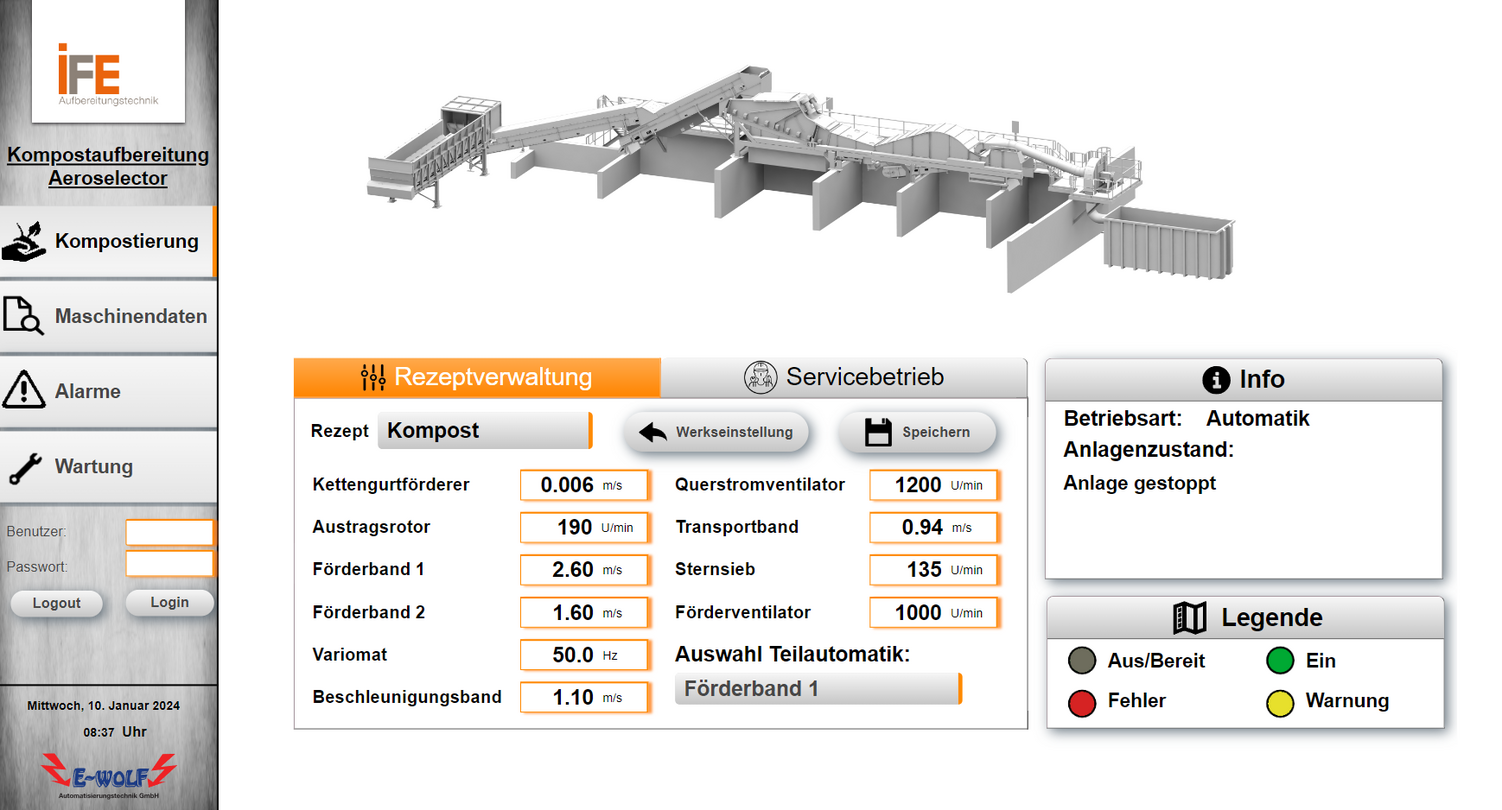

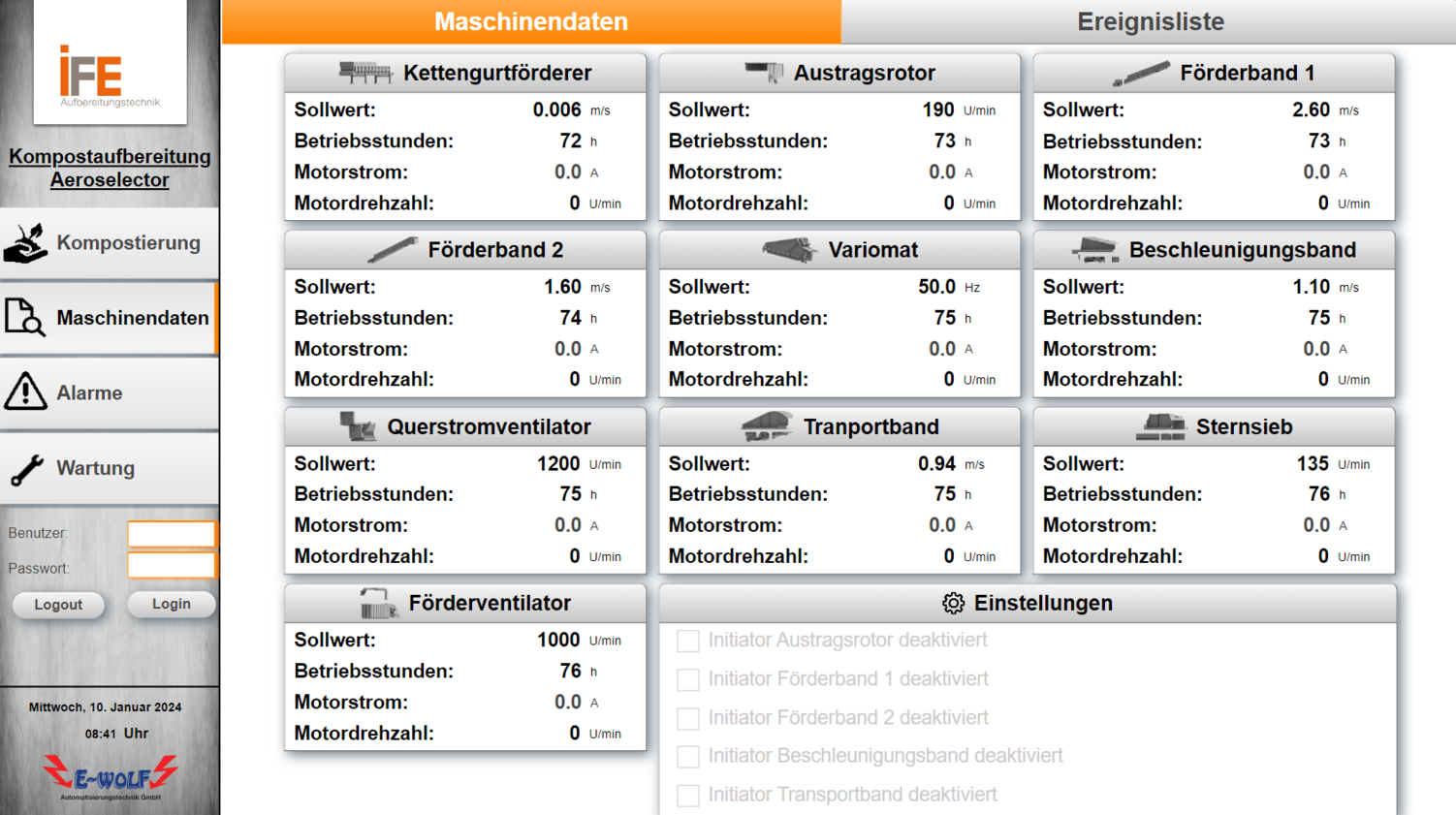

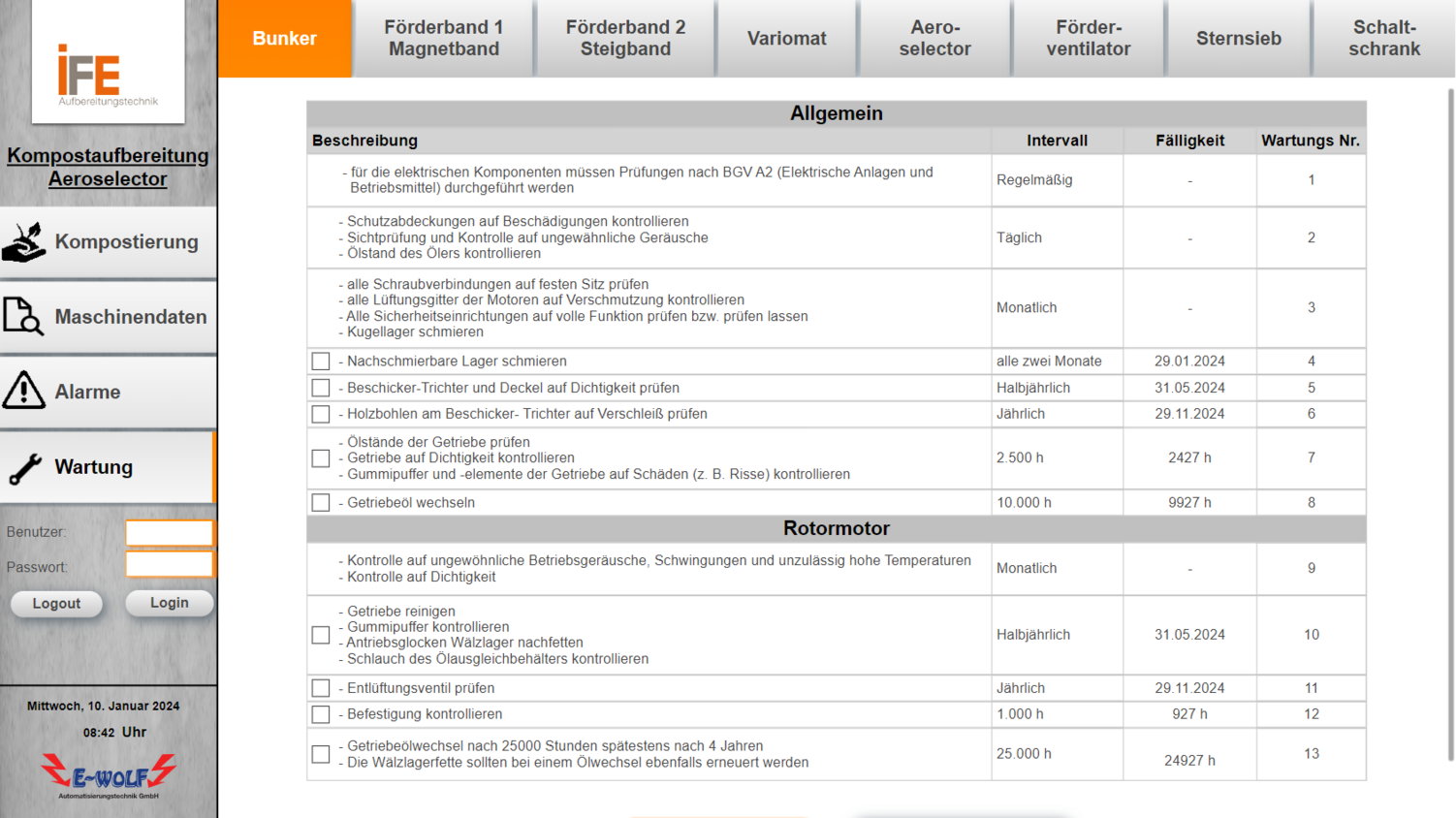

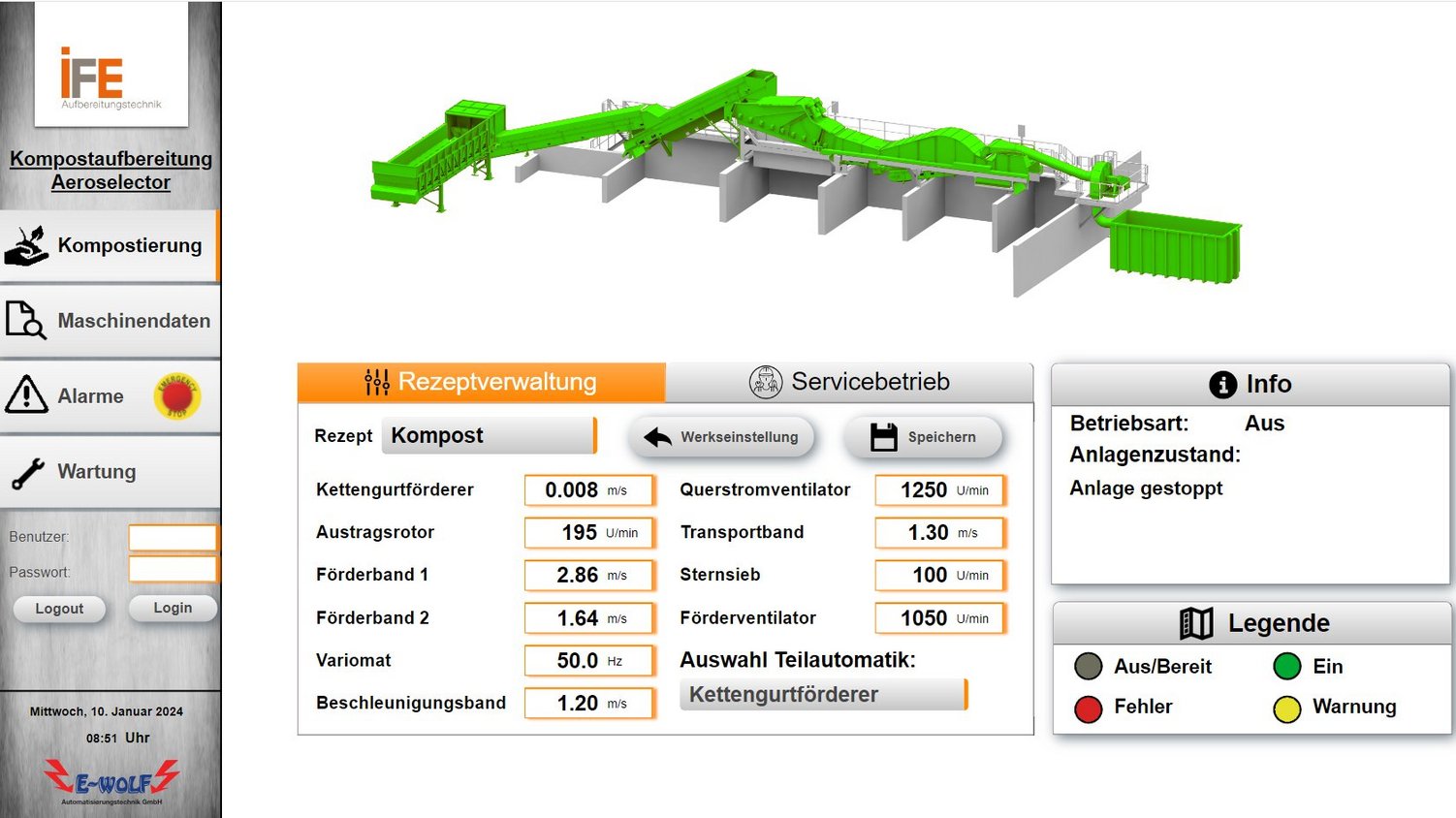

Furthermore, VIVO is already making optimum use of the AEROSELECTOR's advanced control system by defining its own recipes, allowing the machine settings to be adapted to the respective input material in a matter of seconds. In addition, the complete maintenance and lubrication schedule is incorporated into the control system. The next expansion stage will even enable control from the wheel loader, which will make operation even more flexible.

And the conclusion?

“IF YOU WANT TO INCREASE QUANTITY AND QUALITY AT THE SAME TIME WITH MAXIMUM EFFICIENCY, THERE IS NO WAY AROUND THE AEROSELECTOR FROM IFE!”

Christian Schöllner, Head of composting plant, compost consulting & sales at VIVO, was delighted about the processing results and the collaboration.

He greatly appreciates the good communication and the cooperative relationship with the IFE team. Mr. Schöllner is convinced that more units of this kind will be delivered to Germany - in his opinion, the AEROSELECTOR takes compost processing to a new level.

VIVO Warngau

VIVO Kommunalunternehmen für Abfall-Vermeidung, Information und Verwertung is located in the Bavarian Oberland and is responsible for all waste management tasks in the district of Miesbach. It operates the Warngau composting plant - a combined dry fermentation and composting plant. The biogas is utilized to generate electricity and heat, while the compost finds applications in horticulture and landscaping, agriculture, private gardens as well as public areas.