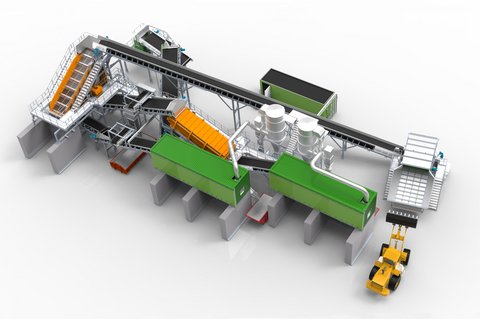

Task: Pre-separation of stones from a mixed coarse compost fraction (=green waste and biowaste) to clean both the compost and the stones.

Solution: IFE supplied a separation station based on successful material tests in the in-house technical centre on an identical but smaller test device. The package solution consists of two IFE vibrating feeders and two IFE destoners, which simplifies the interfaces.

Process steps

The first feeder receives the coarse compost from the conveyor belt and equalises it. The second feeder distributes the material to the two destoners arranged in parallel. It runs transversely above the two separators and is equipped with inclined slots at the bottom to effectively distribute the material onto the subsequent sorting machines. On the destoners, separation into a light and heavy fraction is achieved through vibration and gravity. The lightweight materials (coarse compost) are transported up- and forwards on individual separation plates due to the vibration, while the heavy parts (stones) roll down- and backwards due to their mass. In addition to the inclination of the separation plates, amplitude and speed can also be individually adjusted to achieve the desired separation result.

Task: The operator's aim was to produce pure compost without stones, metals and plastics from rotten fruit, vegetable and garden waste and to obtain a biomass fraction. IFE was commissioned to realize the fractionation and subsequent Fe separation.

Solution: IFE waste screen (coarse screening), IFE TRISOMAT flip-flop screen (fine screening) and IFE permanentmagnetic overband separators for ejecting foreign objects.

The mixture of composted and non-composted material that remains after the composting process should be divided accordingly into: pure compost, biomass, impurities, material for the composting process and a coarse fraction that is discharged.

The new post-processing method should enable the compost produced to be returned to the soil as a high-quality fertiliser. This creates a closed cycle.

However, the moisture in biowaste causes conventional screens to clog easily. The plant operator was therefore looking for a screening solution that would avoid this issue. The seamless integration of these components into the overall planning was another important requirement.

(Image: @Hoving Holland B.V. & Indaver Compost B.V.)

Process details

The IFE waste screen generates three fractions to enable further processing:

- +120 mm,

- 40 – 120 mm,

- 0 – 40 mm.

The combination of stainless steel screen panels with special opening geometry and additional bar sections ensures virtually blockage-free screening and prevents too many long pieces from falling through into the undersize.

0 – 40 mm:

After magnetic separation by IFE, the material stream of 0 – 40 mm is subjected to further screening to achieve additional fractionation (0 – 10 mm and 10 – 40 mm). Fine screening with a separation cut of 10 mm takes place on the IFE-TRISOMAT flip-flop screen. The high acceleration values and the unique 3-phase motion enable efficient screening. The fine fraction of 0 – 10 mm then undergoes a final separation of impurities and is prepared as saleable compost. The remaining fraction of 10 – 40 mm is subsequently cleaned and fed back into the process.

Therefore, IFE screening technology forms the basis for successful post-processing of compost.

Conclusion

IFE's expertise, combined with its extensive portfolio, enables the integration of single machines as well as the provision of an all-in-one solution in the form of the IFE AEROSELECTOR. For more information about the AEROSELECTOR, please visit: https://www.ife-industrial-composting.co.uk/.