Scrap copper and copper alloys…

... infinitely recyclable, without loss of quality!

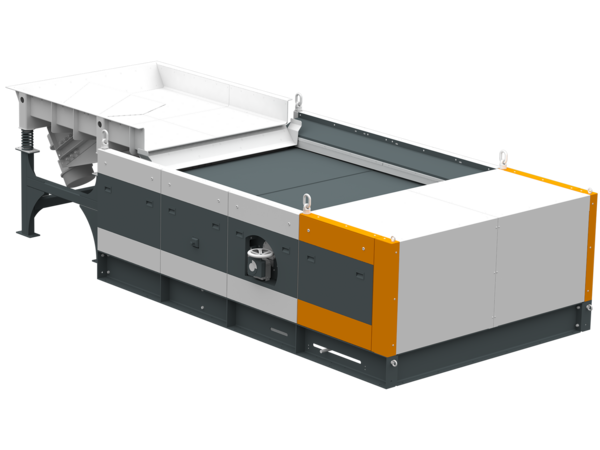

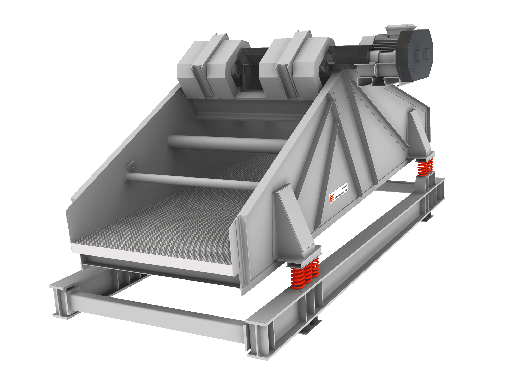

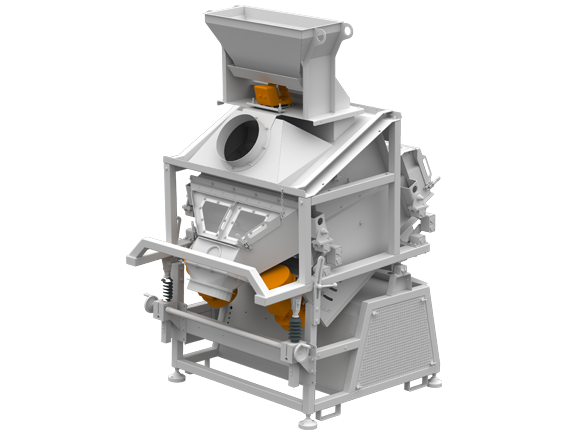

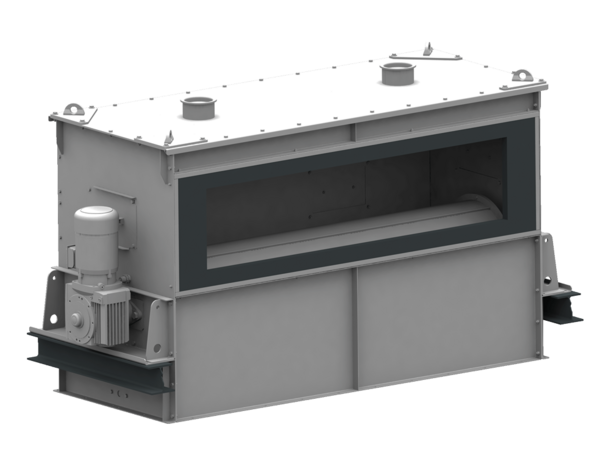

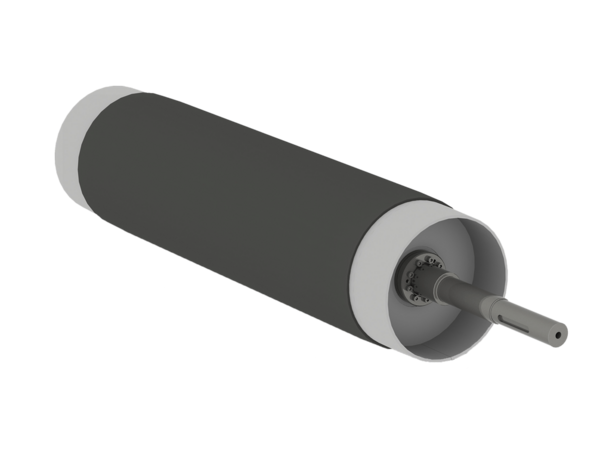

Copper is the most important raw material for energy transmission and grid expansion, but also for the production of renewable energy. In nature, the ores have typical copper contents of around 1%, and the metal has to be dissolved from the ore in complex smelting processes. Therefore, copper scrap recycling is essential for the supply of this metal. With its machines, IFE contributes to the recovery of copper. Primarily pre-shredded electronic or cable scrap is screened in order to dissolve potential lumps and pre-separate plastics. Ferromagnetic particles are separated from the material stream by means of a magnetic drum. An IFE eddy current separator separates a weakly magnetizable fraction, a non-metallic residual fraction (e.g. plastics) and the coppery NE fraction. Last but not least, the IFE SORT takes care of the post-cleaning of the non-ferrous fraction and thus generates a heavy fraction with a copper content of ≥ 99%.

Metal recycling specialist CCR: exclusive insights

Clayton County Recycling's (CCR) Inc. metal recycling facilities are located in the Midwestern United States. They collect, process, recycle and trade both ferrous and non-ferrous metals. The scrap metals CCR receives are primarily from the industrial sector, but also from auto recyclers and various individual contracts (e.g., demolition material from buildings with steel construction). Customers for the metals recovered in this process are steel mills and foundries.