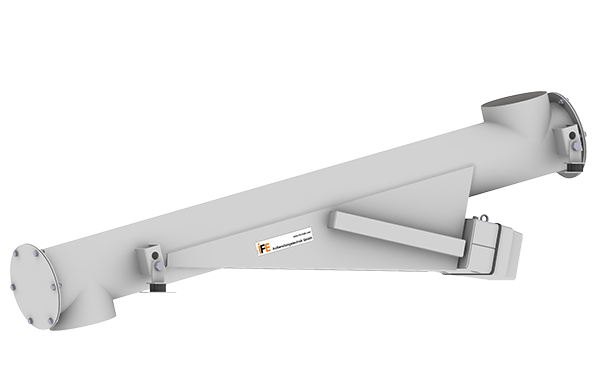

for dosing of bulk material

IFE vibrating tubular feeders with electromagnetic drive are used for bin extraction and for conveying of bulk material. Typically they are used to convey dusty material or used to protect material from ambient conditions. Inlet and outlet can be sealed of by means of elastic sleeves. Applications include dosing, extended feeding of weigh bins, or weigh feeders for steady and smooth feeding for downstream equipment. The vibrating feeders are built in a welded design, driven by an IFE electromagnetic drive.

IFE vibrating tubular feeders are designed and manufactured specifically to the application. Based on clients demand a wide variety of versions are available:

- tube made of mild or wear resistant steel, stainless or acid-proof steel

- multiple inlet and outlet nozzles possible

- manually or automatically operated slide gates

- feeder available on swivel frames for optimized material distribution

- bolted design for easy exchange of tube

- long distances covered by stringed together feeders

Robust and enduring

The IFE electromagnetic drive and the feeder or tube form a vibrating system consisting of two masses. The excitation of the vibration is made by the pumping force of the magnet being connected to the mains via an IFE-control unit. The amplitude of the vibration can be adjusted while in operation. These electromagnetic drives are manufactured for robustness and are dust- and splashproof due to the total enclosed design.

Data

| totally encapsulated tube | with inlet and outlet nozzles |

| nominal length | up to 3800 mm |

| nominal diameter | up to 475 mm |

| unlimited conveying distances | feeders can be stringed together |

| driven | by IFE electromagnetic drive |

| drive placement | underneath or above tube |

| tube material | according to clients specification |

| control of feed rate | by IFE control unit including a frequency converter |