Similar and yet different

Conveying, screening and magnetic technology for all use cases

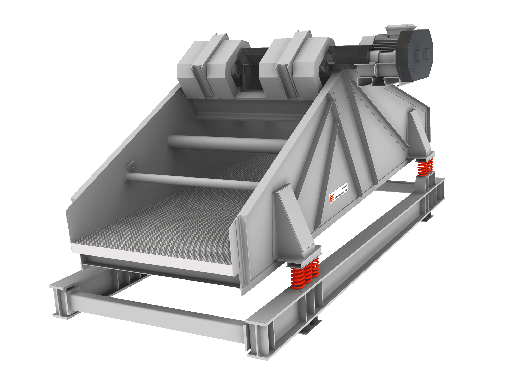

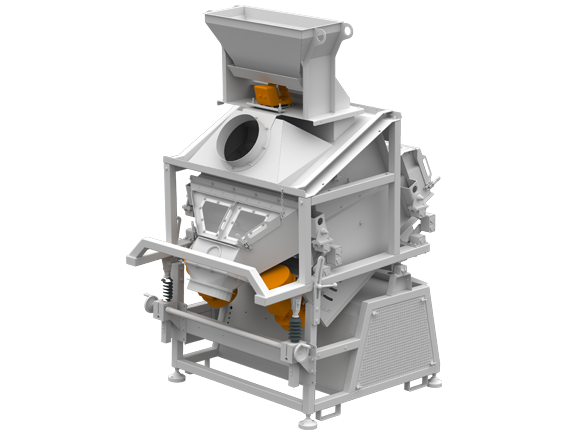

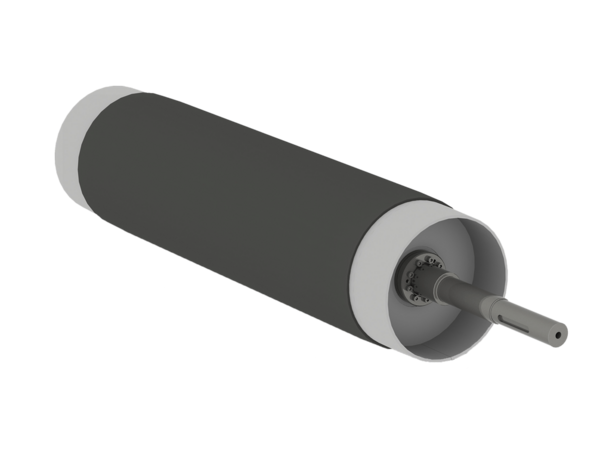

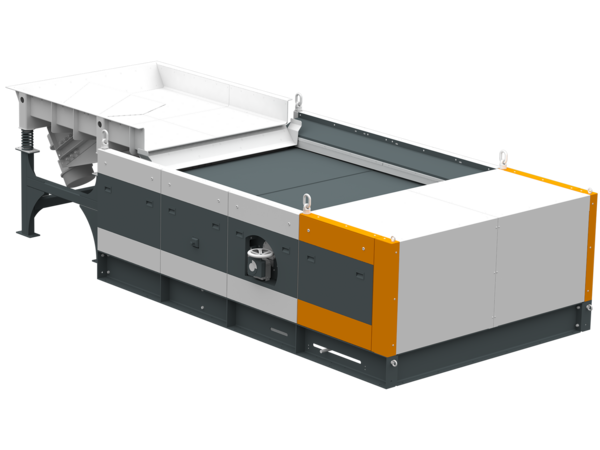

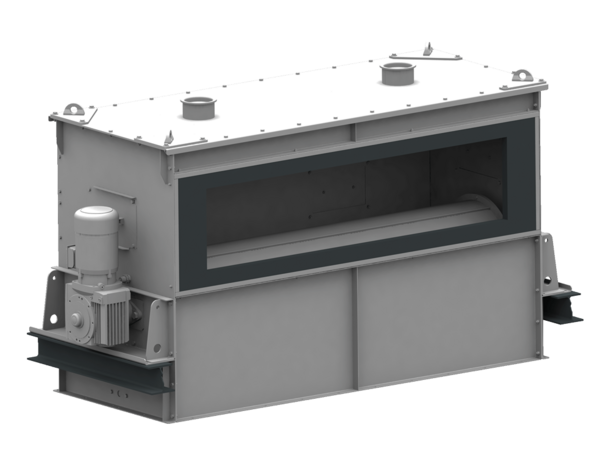

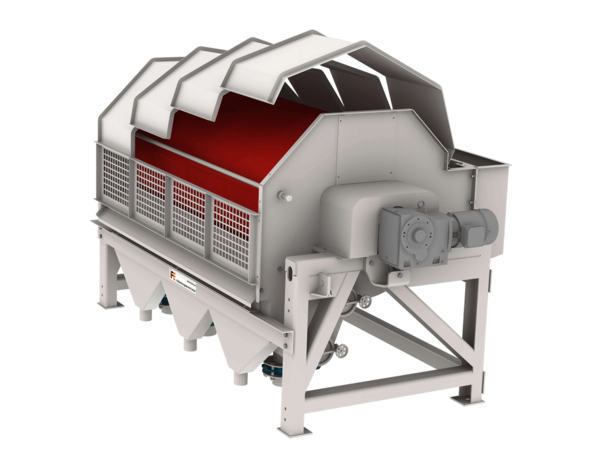

The greatest possible purity of the input materials is a prerequisite in the production of glass products and ceramics to obtain the required product properties. The removal of impurities must be tailored to the downstream production process. For these tasks, IFE supplies individual machines consisting of vibrating feeders, grates and (classification) screens, but also magnetic separators in all possible designs.

How to convert cullet into high-quality industrial products

Glass bead manufacturer SWARCO transforms old fragments of glass into reflective glass beads for road markings. The current article shows the important role, that IFE plays in this process.