Metal extraction by IFE machines

For returning to the recycling cycle

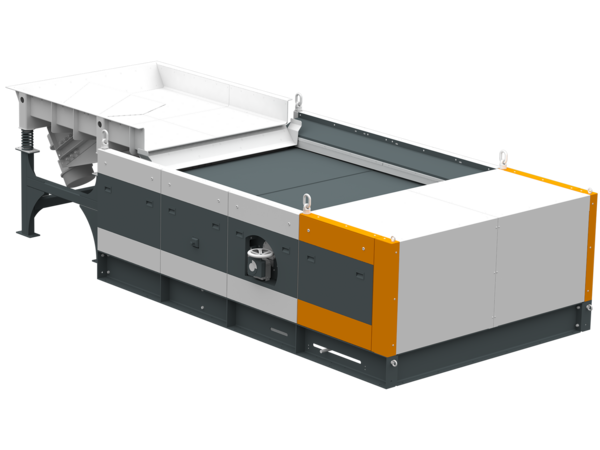

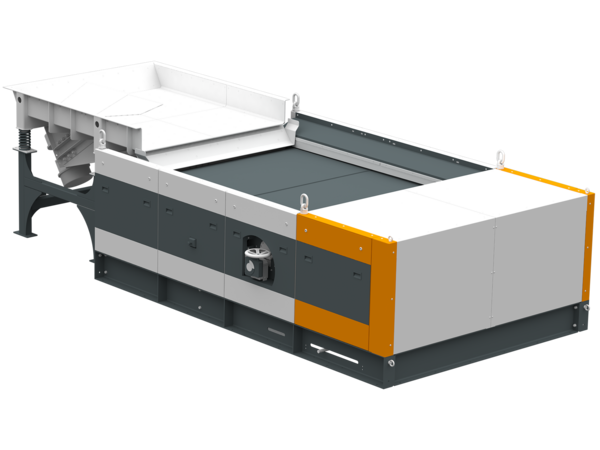

The melting of ores for metal extraction produces slags which, despite careful separation of the melt, still contain significant metals content. In order to maximize the efficiency of the process, it is necessary to return it to the melting process. At the same time, landfill space is minimized respectively metal-free construction materials are produced, which are used, for example, as a cement aggregate. IFE machines separate both recyclables very carefully.

Challenges in the processing of ferrosilicon slag

The Slovak company KOVOHUTY Dolný Kubín, s.r.o., is one of the largest European producers of ferrosilicon powder. *Source KOVOHUTY

The company’s task was to find a suitable process for recovering ferrous heavy metals from FeSi45 slag. The pure FeSi45 fraction, which is considered to be non-magnetic, is used as powder for the production of welding electrodes, for example.

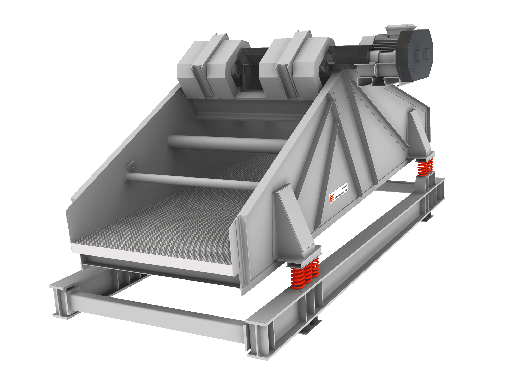

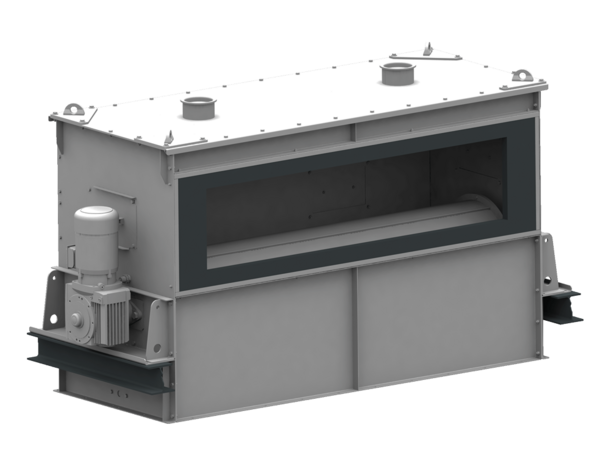

Around 47 % of the FeSi45 slag was successfully separated from the ferrous heavy fraction by means of density sorting. The analyses carried out at the customer's laboratory yielded a recovery quota of 98 % of the metal content. The hopper discharge that was in operation on site provided further optimization potential. In this context, the IFE engineers recommended installing a vibrating feeder with electromagnetic drive to ensure continuous dosing of the FeSi45 slag.