Generate high temperatures with waste

Achieve consistent qualities from highly fluctuating inputs

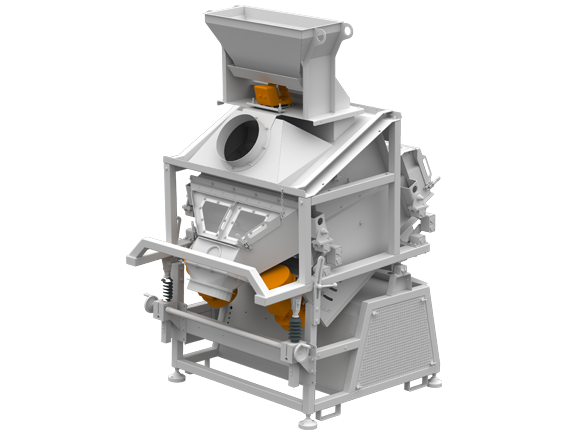

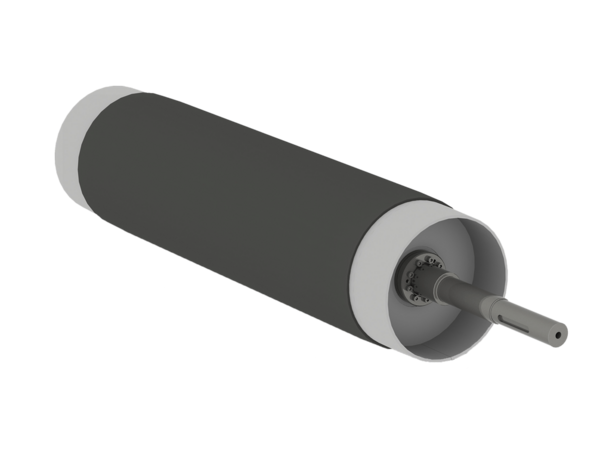

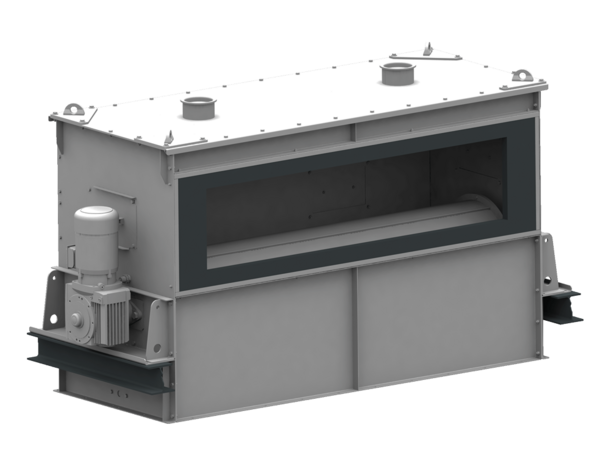

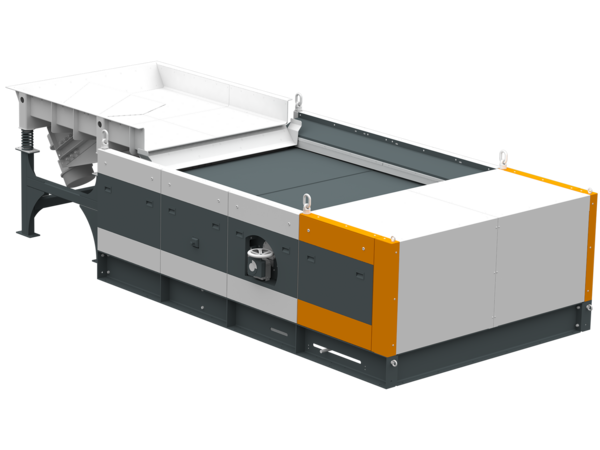

The co-incineration of waste in the form of RDF (refuse derived fuel) is one of the most effective measures for decarbonizing high-temperature processes such as cement production. Special attention must thus be paid to the calorific value-oriented processing of (plastic) waste. IFE supplies individual machines, such as feeders, screens and magnetic separators, adapted to the input material available on site.

Customized processing technology from a single source

For more than 20 years, IFE has been supplying screening, magnetic and conveyor technology for the processing of refuse-derived fuels. They are not only used for removing impurities such as metals and stones. IFE screening machines reliably ensure uniform grain sizes and thus a high-quality end product.