Fractionated and purified

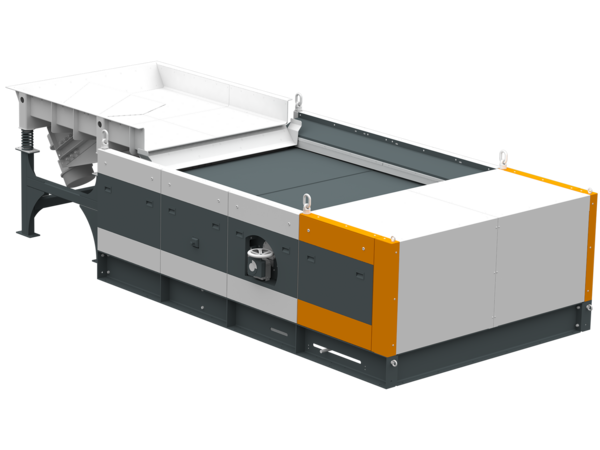

Material handling technology for bottles and packaging made of PET material

In addition to thermal recovery, recycling is particularly high on the list for PET (polyethylene terephthalate), as it can be recycled as often as desired without leading to a gradual deterioration in quality. Used PET is used to make polyester textile fibers or for new PET beverage bottles. In all cases, processes are required to get from the contaminated PET bottle to the cleaned flakes or granules. IFE supplies the appropriate screening and sorting technology for this task.

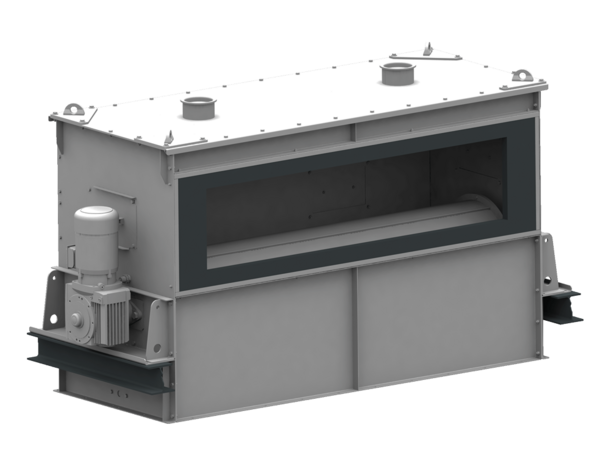

Preparation process PET flakes

Preparation process PET-Flakes If the required raw material is not available in pure form, the temperature control during the melting process can be jeopardized or the die of the extruder can become clogged.

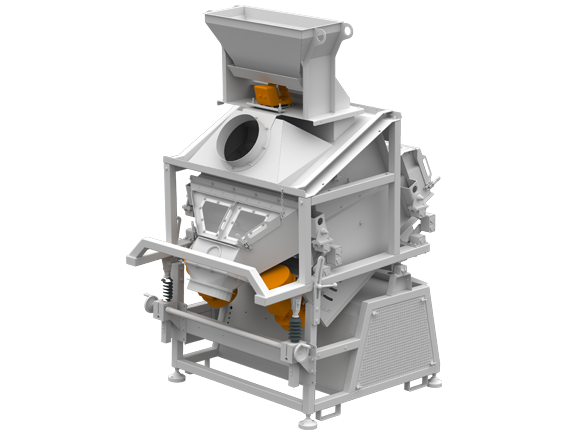

The IFE magnetic technology portfolio offers a wide range of suitable technical processes for efficient Fe/NE contaminant separation.